WHAT WE DO

PLANTATIONS

Grupo Fortaleza’s rubber plantations with over 10,000 hectares, which are FSC certified, focused on sustainability that add economic, environmental, and social value to the regional economy. In the environmental part, the plantations of Grupo Fortaleza have protected areas where endemic fauna and flora of the region are housed. In the social area, they focus on adding value to the communities that surround the plantations by providing education, drinking water, health, and wellness.

A rubber forest is a plantation

with tall and imposing leafy trees

A rubber forest is a plantation

with tall and imposing leafy trees

Well-Beign At Work

Our plantations provide work to many people due to their high need for labor. An average plantation of 45 hectares can provide work for up to 20 people who have a direct impact on their families.

Long-Lasting, Efficient Trees

Every rubber tree, with a life span of +40 years, is tapped on average once every week. Thanks to its physiological characteristics, the tree provides the latex or cup lumps from the sucrose generated by the trees leaves which is used to produce everyday products like tires, gloves, balloons, and even latex beds and pillows, to name a few.

Sustainable Flora & Fauna

Our rubber forests house a diverse variety of flora and fauna that contribute to the natural and sustainable development of the plantations, adding value to our compromise with the environment and the life forms it shelters.

Well-Beign At Work

Our plantations provide work to many people due to their high need for labor. An average plantation of 45 hectares can provide work for up to 20 people who have a direct impact on their families.

Long-Lasting, Efficient Trees

Every rubber tree, with a life span of +40 years, is tapped on average once every week. Thanks to its physiological characteristics, the tree provides the latex or cup lumps from the sucrose generated by the trees leaves which is used to produce everyday products like tires, gloves, balloons, and even latex beds and pillows, to name a few.

Sustainable Flora & Fauna

Our rubber forests house a diverse variety of flora and fauna that contribute to the natural and sustainable development of the plantations, adding value to our compromise with the environment and the life forms it shelters.

FACTORIES

As a latex-oriented company, we are deeply committed to sustainability, social responsibility, and legislative compliance. We strive to ensure that our practices are environmentally conscious and contribute positively to the communities in which we operate. In line with our dedication to upholding ethical standards, we rigorously follow all relevant laws and regulations, ensuring that our production processes meet the highest compliance standards.

Natural Rubber Processing

Centralized Processing and technology unit.

Natural Foam Products

As part of the vertical integration in the natural rubber industry,

DISTRIBUTION

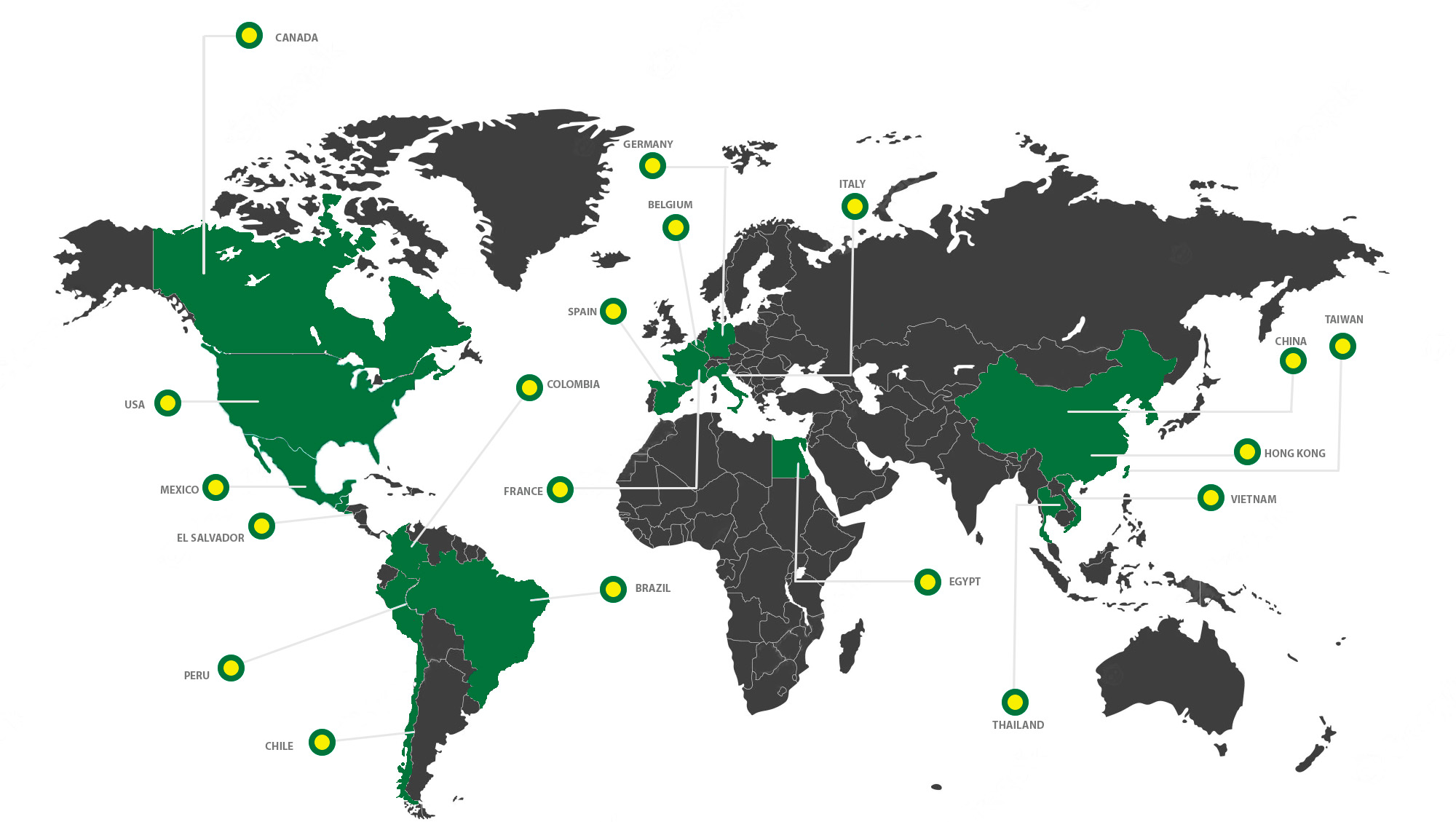

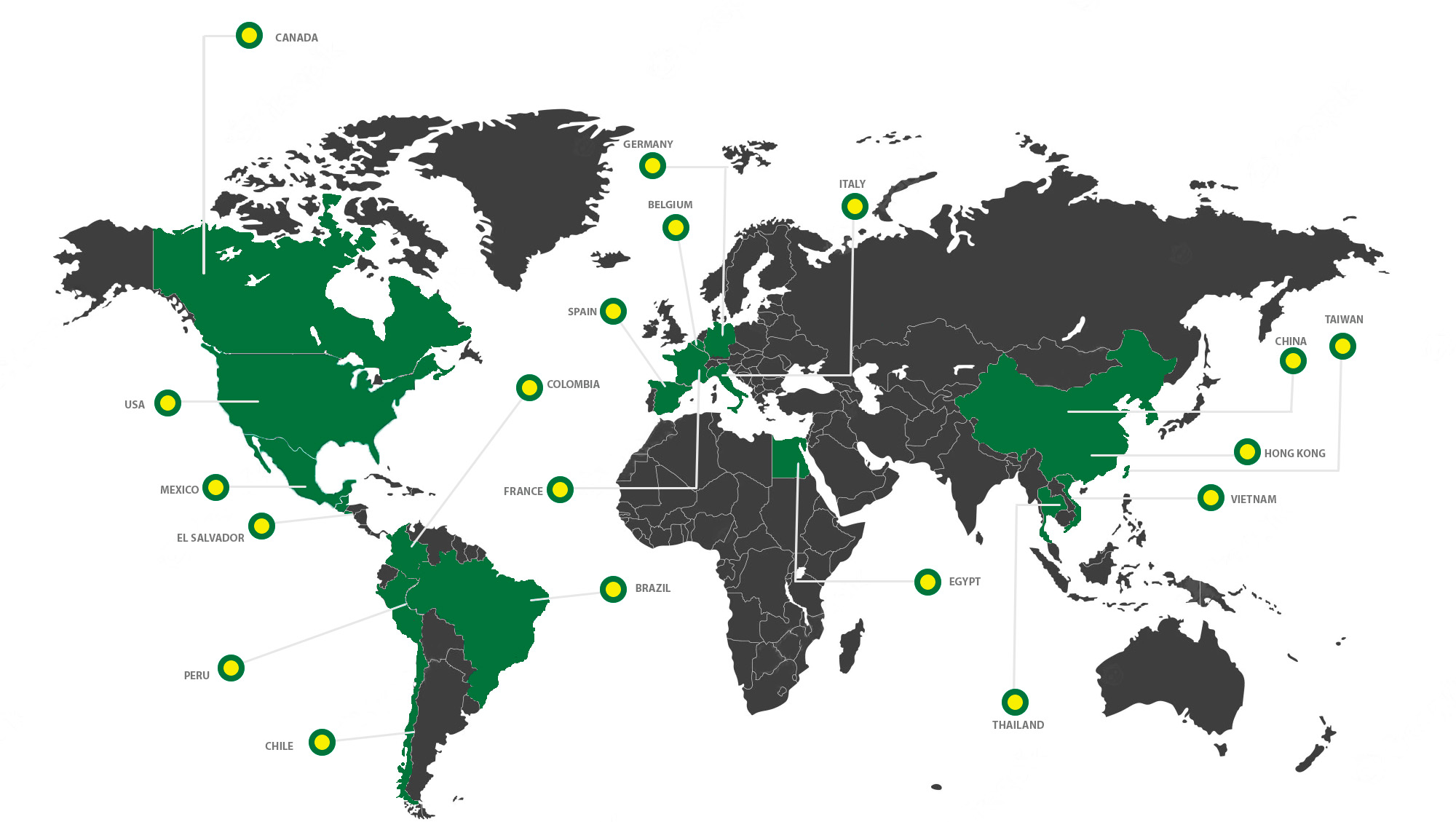

GFT is also certified FSC which ensures traceability in all documentation and operations. GFT is our commercial office, in charge of unifying all our plantations products under a single recognized brand. It manages all our commercial relations trying always to provide the best customer experience and service.

We export to over 20 countries over the world.

We export to over 20 countries over the world.